How To Install Inverter And Battery

Introduction

The success of a DC to Ac power inverter installation depends mainly on the methods and materials used for the installation. Depression DC input voltage inverters (12 or 24 Volts DC) crave high DC input currents. For instance, to provide a service of 15 Amperes at 120 Volts Air conditioning (1800 Watts) from a 12 Volt battery, the DC electric current will approach 180 Amperes! How can we supply such a high current to the inverter safely and efficiently? This article volition guide you through a successful power inverter installation.

We are kickoff with the assumption that the primary three system components - inverter, bombardment, and alternator - have all been chosen. While installing and wiring these components we will follow the standards and recommended practices described by the:

- National Fire and Protection Clan (NFPA)

- National Electric Lawmaking Handbook- NEC 96

- Society of Automotive Engineers (SAE)

- SAE Handbook Volumes 1-4

Inverter Installations

Using the Existing Alternator and Battery, what are the system limits for a practical inverter installation using the existing nether-the-hood alternator and bombardment? A bulk of utility vehicles have a 100 to 130 Ampere alternator together with one or ii group-27 batteries. Although the alternator cannot go along up with a continuous full-load current demand of more than 50 Amperes, it can provide plenty for brusque term power use. In many cases the use of electrical power to exercise work is intermittent (using tools off and on for short periods of time). In these cases the alternator is able to "keep up" with power use and recharge the bombardment. There have been many successful installations of a 2300 Watt inverter in such trucks.

Other successful, smaller installations consist of an 1100 Watt inverter arrangement in a smaller utility van or truck:

- Alternator rated at least 85 Amperes.

- A deep-cycle battery, Group 27 or larger in size.

- Wire from the inverter to the battery is 2 gauge at up to fifteen feet (one mode distance)

Where larger inverters than these are used, or where more than continuous ability is required, information technology is recommended that a bombardment pack exist installed equally close as possible to the inverter and that the alternator system be upgraded.

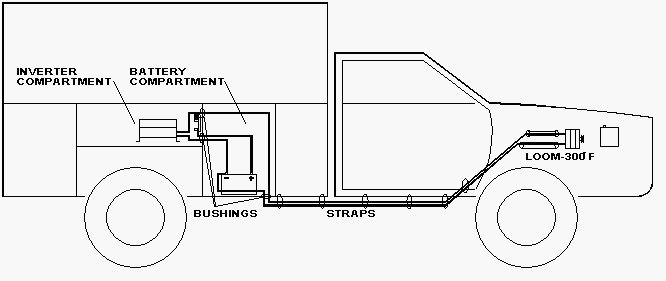

Inverter Installation (refer to Effigy 1) Compartment:

The ability inverter is an electronic device and is therefore somewhat sensitive to external factors. Temperature extremes, moisture, and air-borne contagion which volition be drawn into the housing whenever the cooling fan runs - can shorten life. Some areas to avoid mounting the inverter are nether-the-hood, on the flooring over the exhaust system, or in sealed areas where moisture could condense. The ideal inverter compartment should exist a clean, dry, cool compartment with some ventilation. Annotation that the inverter cannot share an area where flammable fuel vapors exist considering switching components could cause ignition. Corrosive battery fumes should also not be present.

Mounting the Inverter:

Bolt the inverter securely on either a platform or bulkhead. Leave at least one inch of space all around the cabinet and specially to a higher place the cabinet for warm air to move out. The inverter confront and the side where large DC cables enter should be visible and accessible for ease of wiring, ground fault interrupter testing and status lights viewing.

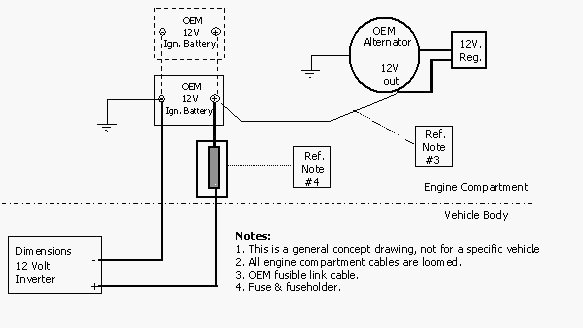

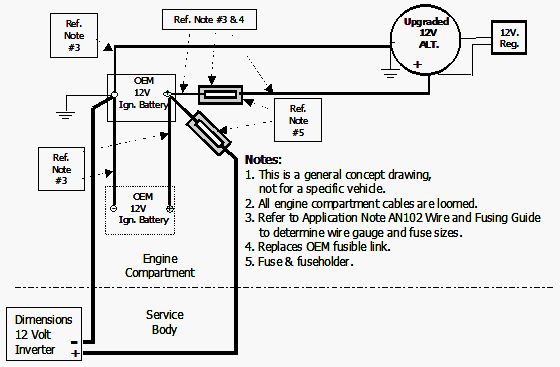

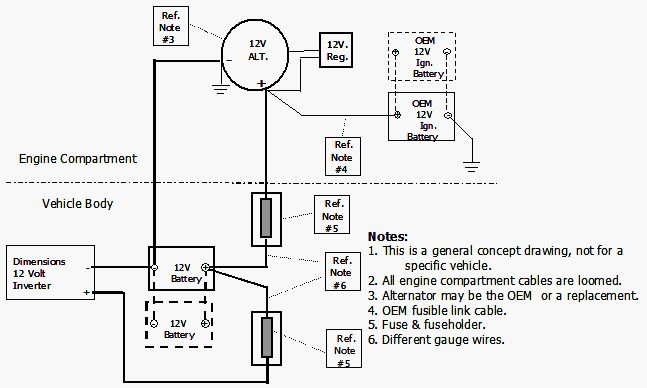

Fuse Holder Installation:

All wiring from a bombardment must be protected with the proper size fuses. All fuses and fuse holders should exist located within xviii inches of the bombardment (Figures ii through 5). Additional fuse holders may be required if the inverter is continued to the engine battery instead of the alternator, or if the under-the-hood wiring is upgraded. The auxiliary battery fuse protects the wires to the inverter and the wires to the alternator. Another fuse holder must be mounted at the engine battery if a direct connectedness is made. These auxiliary battery fuse holders must non be installed in an airtight battery compartment because of the explosion hazard mentioned earlier. Mount the fuse holders in a user-friendly place within eighteen inches of the battery and label the fuse rating adjacent to its holder. Exercise not identify the fuses into the fuse holders until all wiring has been completed.

Battery Installation Compartment:

The battery area must exist vapor-tight to the interior of the vehicle and vented directly to the outside. Information technology must be causeless that hydrogen gas is continuously evolving from the battery. This gas is lighter than air and will quickly escape through openings at the top of the compartment. Openings at the bottom of the compartment will let in replacement fresh air. Install several vent-plugs within one inch of both top and bottom of this area. Note that the battery cannot share an airtight area containing spark-producing equipment, such as the inverter or fuses which could ignite the hydrogen gas.

Mounting the Battery:

Mount the Bombardment using hold-downs, trays, or boxes. Secure to a level, make clean surface. Battery boxes must be of the vented blazon to permit for the escape of gases. Allow infinite around the battery and especially above the battery for ventilation, inspection, and maintenance. The battery should not move more than than 1 inch in any direction, even if upside-down. A framework of angle iron, together with a protective cover, can be made for big systems.

DC Wiring:

1. Employ SGX cable

- SGX cross-linked polyurethane cable complies with SAE J-1127 and vehicle manufacturer requirements.

- SGX insulation meets the high temperature requirements (125°C.) of J-1127.

- Refer to AN102 to determine the proper gauge cable and fusing for your application.

- Sensata can supply consummate cable assemblies with fuse and fuse holders.

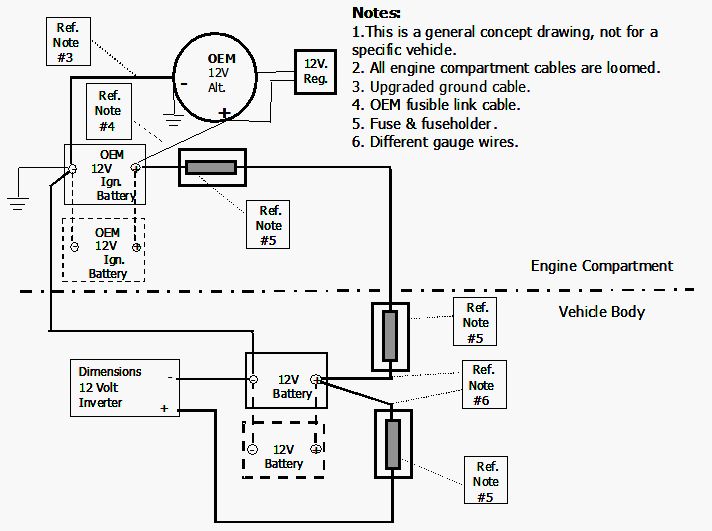

two. Cabling diagrams

- Figure ii and 3 are diagrams for a smaller inverter (1000 Watt or less) where no auxiliary battery is existence installed.

- Figure four is a diagram for a larger inverter (1000 Watt or more than) where one or more auxiliary batteries are being installed.

- Figure five is a diagram for a larger inverter where ane or more auxiliary batteries are being installed and cabling is to the OEM battery.

iii. Routing the cables

Refer to Figure 1. Run both charging cables directly to the alternator. Practise non use the vehicle chassis as a conductor.

- When going through a sectionalisation, use a protective safety grommet to forestall abrasion of the insulation. Seal the backlog opening with caulk to prevent fume entry.

- When routing nether the vehicle, secure the cables with clamps every eighteen inches, to prevent a snag. Go along the cables away from the drive shaft, frazzle system, and fuel line.

- When routing in the engine compartment, use high temperature (300°C.) loom and route the coolest mode possible.

AC Wiring:

Air conditioning wiring must exist stranded copper conductors for vibration resistance and must also be protected by a conduit. Route closely to the frame. Use electrical tape over the wire nuts at the terminations because they can be loosened by vibration.

i. Use "Boat and Truck Cable" for up to x AWGUL listed, meets DOT specifications

- Stranded copper

- 16 to 10 AWG

- Nonmetallic

two. Use Type NM-B cable or Individual Building Wire conductors above 10AWG

- UL listed

- Stranded copper

- Nonmetallic

3. Utilise conduit

- Metallic: utilise rigid Electric Metallic Tubing

- Nonmetallic: utilise rigid PVC

four. Utilize junction and outlet boxes that friction match the selected conduit organisation

v. Bonding Connect a # 8 gauge stranded copper wire from the bonding lug on the inverter chassis to the vehicle chassis. The connections must be tight against bare metal. Use star washers to penetrate paint and corrosion. This safety requirement also reduces radio interference (the Dimensions Inverter is UL listed, its DC input connections are isolated from the chassis).

Figure 1 Cable Routing for Inverter Installation:

Guidelines for Fusing between Inverter, Batteries, and Alternator

All fuses within xviii" of battery - Ref: 1996 NEC article 551-x (due east)-(4)

Figure 2 Inverter Cabling Diagram (thousand watts or less), no auxilliary battery(s), OEM alternator:

Figure 3 Inverter Cabling Diagram (1000 watts or less), no auxilliary battery(s), upgraded loftier output alternator:

Figure iv Inverter Cabling Diagram (1000 watts or less), with auxiliary bombardment(southward) (preferred method)

Figure 5 Inverter Cabling Diagram (1000 watts or less), with auxiliary battery(s)

DC WIRING

Terminating the cablevision:

Cutting the cable using a shear-blazon cable cutting tool (effigy half dozen). Strip the insulation from the cable using a rotary type cablevision stripper tool (figure 7).

Bombardment connections tin can be made with band (figure viii) or clamp (effigy 9) terminals. Make alternator connections with ring terminals. Use 5/16" ring terminals for the fuseholder connections.

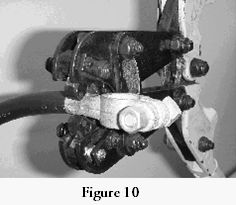

Crimp terminals using a long-handle multi-dice crimping tool (figure ten).

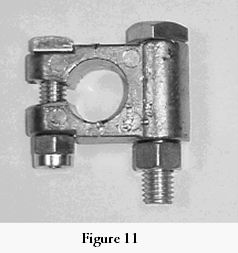

When two cables must exist connected to a single battery mail, use a post clamp type terminal (figure 11).

All engine compartment wiring and cabling must be in high temperture (300 degrees C) loom (figure 12).

Source: https://www.magnum-dimensions.com/knowledge/installation/power-inverter-installation

Posted by: rodriguezwitarsted.blogspot.com

0 Response to "How To Install Inverter And Battery"

Post a Comment