How To Install Rigid Dryer Duct

by Nick Gromicko, CMI® and Ben Gromicko

Updated November 2022

According to InterNACHI's Standards of Practice, home inspectors are required to audit the mechanical exhaust system for the wearing apparel dryer. The clothes dryer must vent directly to the outdoors, unless it is a ventless dryer equipped with a condensate drain (a listed and labeled ductless condensing dryer).

Devices that permit moisture and estrus to vent back into the dwelling should not be used. Dryer exhaust ducts must stop at the exterior of the building.

Moisture

A clothes dryer volition vent about a gallon of water for each load of laundry. If the dryer vent discharges into a crawlspace, cranium, or other edifice cavity, the potential for moisture-related impairment is pregnant. Clothes dryers must vent directly to the outside.

Dryers should use approved exhaust ducts. Ducts made of vinyl, nylon or foil are not recommended. If used, they will void the warranty of most dryers. Screw-duct designs often trap lint, which can clog the duct, requiring the dryer to work harder and longer to dry out clothes and causing it to increase the dryer's temperature. Not but is a poorly exhausting dryer less efficient, information technology can also be a burn down adventure due to the flammability of the accumulated lint. The use of PVC pipe for dryer exhaust ducts is also not allowed by modern building standards.

Metal

According to the International Residential Code (IRC) Department M1502, the clothes dryer exhaust duct should be fabricated of metallic, with No. 28-estimate thickness, a smooth interior end, and a duct diameter of four inches.

A domestic dryer exhaust power ventilator may be installed for exhausting the dryer duct organization. Information technology must adapt to the UL 705 standard and must be installed co-ordinate to the manufacturer's recommendation. The maximum length of the exhaust duct must be determined past the manufacturer'southward instructions for the ventilator.

Maximum Length

Curt, straight, horizontal duct runs are the about efficient. The size and maximum length of the exhaust duct shall be adamant by the dryer manufacturer'southward installation instructions and must comply with local building code.

One best practise is a duct length of no more than 35 feet from the connection to the transition duct to the outlet terminal (exhaust termination point). This maximum length is reduced by the types of exhaust duct fittings. The 2022 IRC M1502.4.five.ane describes those reductions.

| DRYER EXHAUST DUCT Plumbing equipment TYPE | EQUIVALENT LENGTH |

| four-inch radius, mitered 45-degree elbow | 2.v feet |

| four-inch radius, mitered 90-degree elbow | 5 feet |

The maximum length of the exhaust duct does not include the transition duct.

Transition

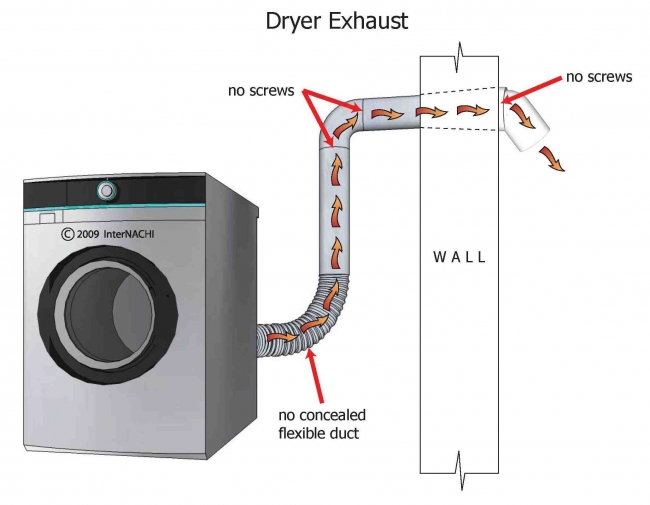

The transition duct (the visible piece of duct connecting the dryer to the wall area) can exist up to 8 anxiety long and should be listed in accordance with UL-2158A. There are some semi-rigid metallic transition duct products that are UL-listed. Transition ducts must be visible. The transition duct must non exist concealed within construction.

Garage

A good technique is to restrict the dryer exhaust duct from passing through an attached garage. Ducts in the garage or penetrating the walls or ceilings separating thedwellingfrom the garage must be synthetic of minimum No. 26-gauge canvass steel or other approvedfabric, having no openings into the garage.

Support

The duct should be secured in place and supported at intervals not to exceed 12 anxiety. I all-time practice recommends supports installed at 4-pes intervals. Sags in the duct must exist avoided.

Termination

The exhaust duct should stop outside the building at least 3 anxiety from any building opening, and at least 10 feet from an air conditioner or heat pump condenser (reference). The duct termination should be fitted with a closeable gravity or automatic damper (a backdraft damper). A screen may not be installed at the duct terminus, as it tin trap debris, which poses a fire take chances.

How to Inspect the Dryer Exhaust Duct

- Look for a rigid metal (aluminum or galvanized steel) frazzle duct connecting the transition duct to the exhaust duct outlet concluding. The exhaust duct should be rigid metal, 4 inches in diameter, and no more than 35 feet in length (or as specified by the duct manufacturer). This length should be decreased past 2.5 feet for every 45-degree bend the duct makes, and 5 feet for every ninety-degree bend. Check that any joints are installed in the management of air flow.

- Check that the duct is supported at least every four feet and at all joints. There should not be any sags. Joints tin can be air-sealed (ordinarily done with foil tape) and mechanically fastened.

- At the interior wall, the exhaust duct should connect to a transition duct that connects directly to the dryer. The transition duct should be UL-2158A-listed and should exist no longer than viii feet. Short, directly, semi-rigid metal transition duct is preferred. The ducts should be joined with clamps or foil tape. Screws or similar fasteners that tin can protrude into the inside of the duct and grab lint must non exist used.

- Check that the exhaust terminates at to the lowest degree 3 feet from all doors and windows, and abroad from the fresh-air intake of a loftier-efficiency furnace, h2o heater, and any other HVAC intake. It should likewise be located away from air conditioning and rut-pump condensing units installed outside. Terminating the dryer duct at the roof (depicted below) should exist avoided. A best practice is to have the exhaust terminal located so that the exhaust duct will run horizontally with a slightly downward slope (1/iv-inch per foot) to reduce the possibility that condensation will class.

- At the terminating stop of the exhaust duct (at the outside wall), look for a backdraft damper. The hood opening should point downward and should exist at least 12 inches above the basis. No screen should be installed at the duct terminus. Flashing and caulk at the exterior wall penetration should exist installed.

- Especially in cold climates, ducts in unconditioned spaces should be insulated to prevent condensation from forming.

Hazards

The leading cause of fires from clothes dryers is the failure to clean the lint and other debris that can accumulate in and around them. Inspectors tin can make the following recommendations to their clients:

- Always use a lint filter or screen.

- Clean the lint filter before or afterward each load of laundry.

- Remove any visible lint within the dryer.

- At least once a yr, have a professional technician clean the dryer exhaust pipe.

- Gas dryers should be cleaned and serviced regularly by a professional person.

- Follow the manufacturer's operating instructions and don't overload the dryer. Also, don't attempt to dry out soaking wet laundry that hasn't been wrung out or gone through a washing machine's spin bike to remove excess wet.

- Turn off the dryer when leaving domicile and before going to bed.

- Install a burn extinguisher in the laundry area.

- Install a smoke alarm in the laundry area.

- Install a CO alarm in the laundry area for a gas dryer.

Summary

A home inspector is non required to audit for or know near a specific manufacturer's recommendations or the local applicable codes, and the inspector will not be able to confirm the dryer vent's compliance with them. The dwelling inspector may be able to report upon observed indications of defects at the time of the inspection that may crave farther evaluation past a qualified professional.

References

Source: https://www.nachi.org/inspecting-dryer-exhaust.htm

Posted by: rodriguezwitarsted.blogspot.com

0 Response to "How To Install Rigid Dryer Duct"

Post a Comment